OUR PRODUCTS & SOLUTIONS

The Gas Professionals

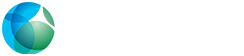

Leeden NOX produces and supplies numerous gas products in various delivery formats to the region, with specific strength in the supply of electronic gas to semiconductor & electronics industry segments. We operate multiple gas production and processing facilities in Singapore, Malaysia and Indonesia. Beside supplying gas products, Leeden NOX also offers engineering & consultancy services, project management and total gas management.

Leeden NOX draws upon the technological expertise from our parent company—Nippon Sanso Holdings Corporation (NSHD), which is Japan’s largest industrial gas producer and among the top five industrial gas suppliers in the world. Our sustainability journey has already begun and we are committed to contribute solutions to address environmental and social issues.